Product and services

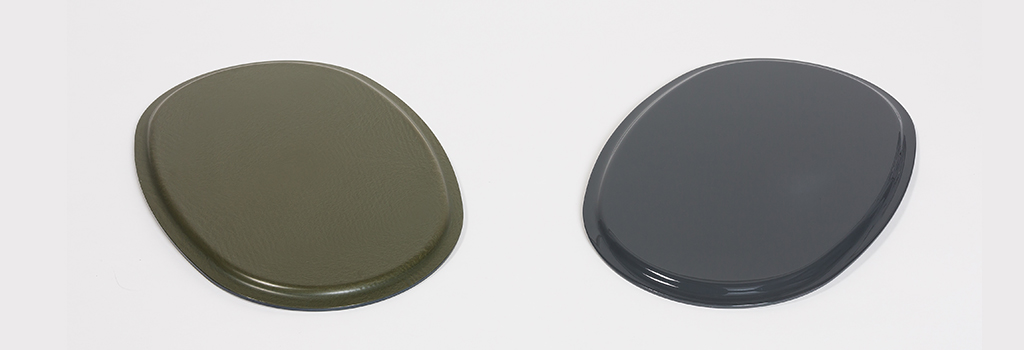

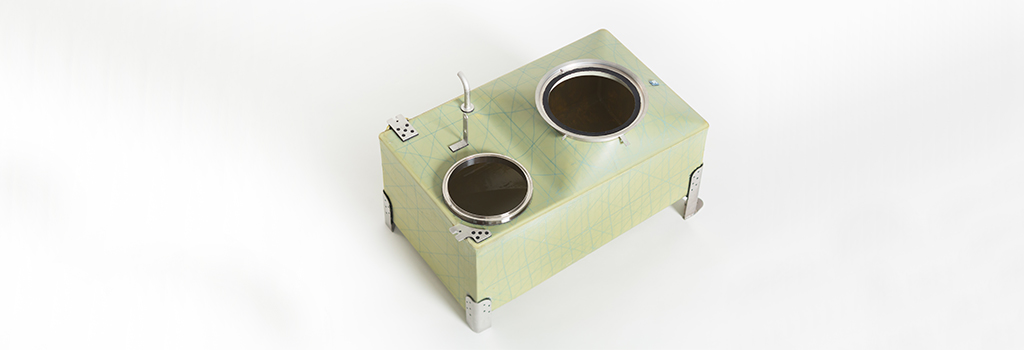

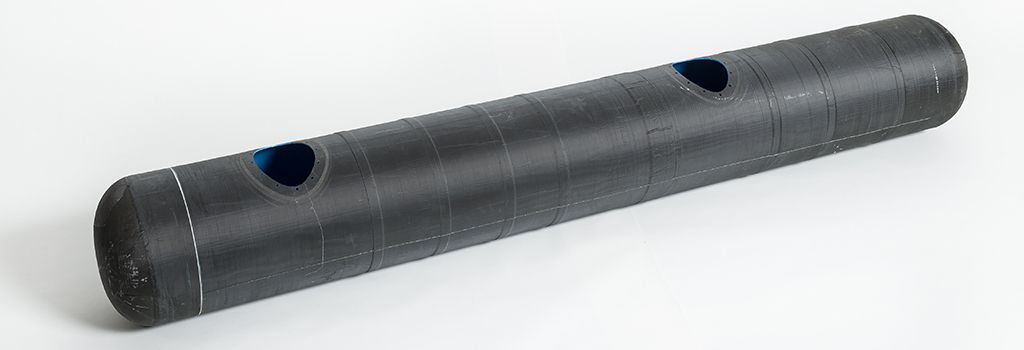

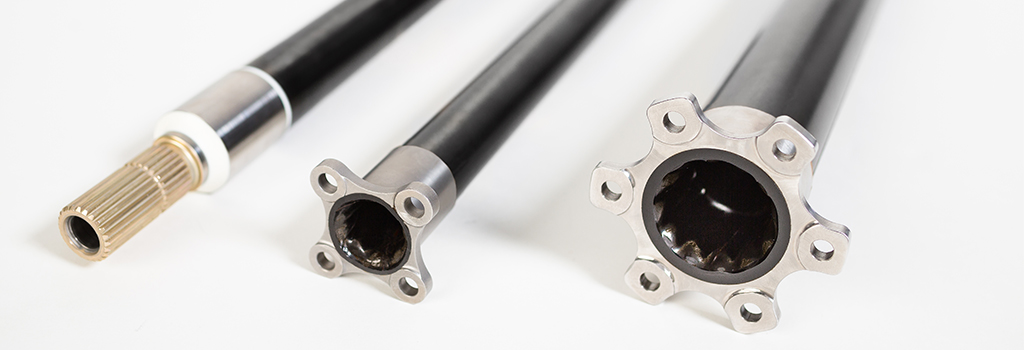

The increasing demand for weight reduction in aeronautics and automotive engineering meets COTESA through a broad spectrum of fiber composite components for CFRP primary structures, fiberglass interior and exterior components as well as components such as drive shafts and tanks. The standard production of parts and assemblies for aerospace, automotive and industrial applications ranges from 1 to several thousands per year.

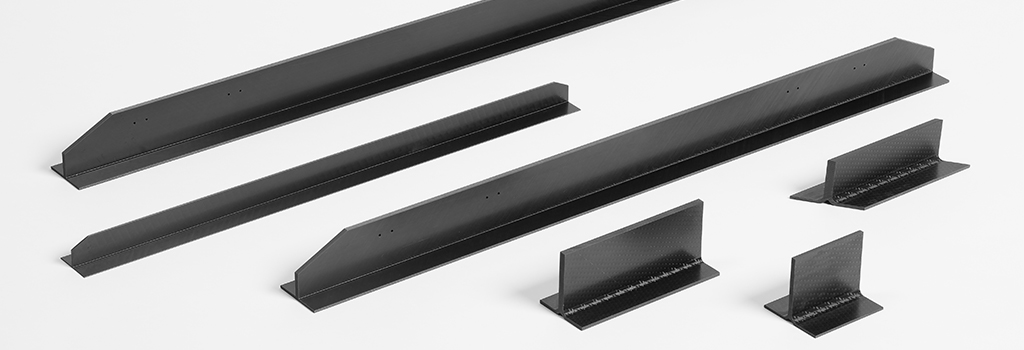

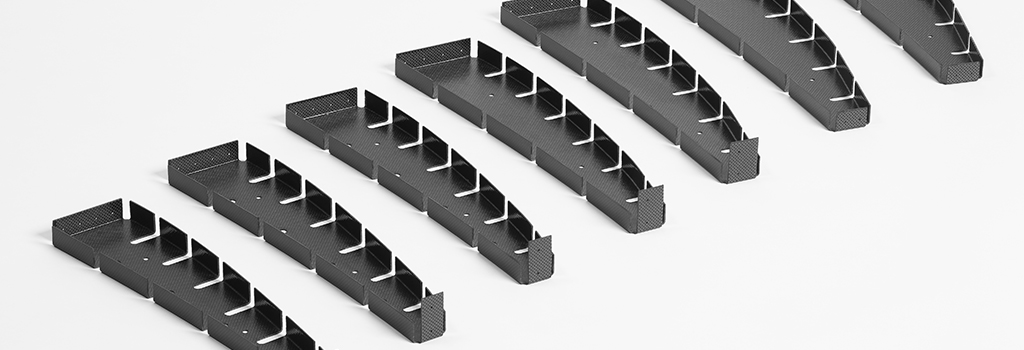

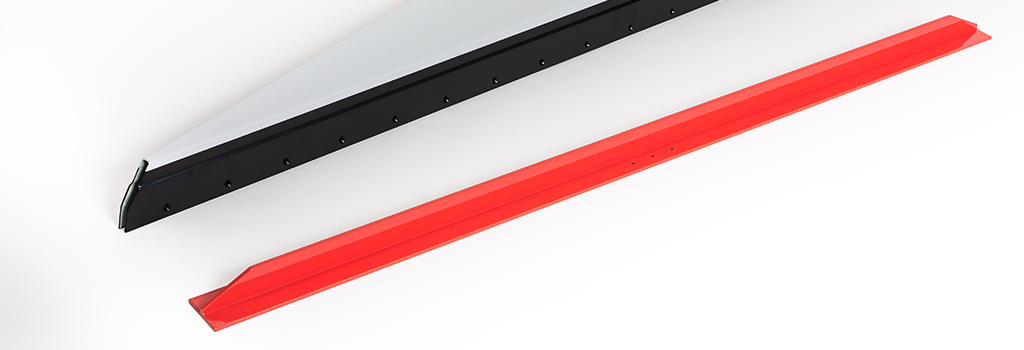

As a supplier, COTESA GmbH produces fibre composite parts for structural applications in the Prepreg autoclave procedure under the quality-technical requirements of the aviation industry. For example, profile structures of many different cross-section shapes form a great part of the component range. One challenge here is in compliance with the required component thickness tolerances in the radius area of U-shaped structures.

Industrial process management

- Lean Management

- Electronic order control – electronic order processing from material management to delivery

- KVP: continuous improvement process as basic principle in quality management

- CAQ: computer-supported quality assurance

- Risk management system

- Configuration management

- REACH-conformity (EU-import regulation of chemical materials and substances)

Materials laboratory

- Material and material testing

- component testing

- Optical 3D measurement

- Consulting in the area of fiber composite production and material testing

- Test specimen production and mechanical processing / specimen preparation

- Consultancy in the field of heat treatment systems according to AMS2750 and CQI-9

Since 2015, the materials laboratory has been accredited as a testing laboratory in accordance with DIN EN ISO/IEC 17025 and also has various "customer-specific" certifications for certain test procedures and standards.

Construction and calculation

- Creation of construction concepts

- Material qualification in our own test laboratory

- Component construction and component design with CATIA V5

- Test specification

Technology development

- Design of production systems

- Tool and device construction

- CNC programming of the machining steps

- Process optimization

Production

- Serial production of parts and assemblies for aviation, automotive and industrial use

- From piece number 1 to several thousand per year